Article

Navigating emerging mining markets: delivering critical mineral projects scross Africa and Mongolia

Renewable natural gas (RNG) or substitute natural gas (SNG) production is one of the most flexible approaches to decarbonise end demand such as residential heating and transportation systems.

Renewable natural gas produced from biogas, power-to-gas and biomass gasification, is a clean and low-carbon alternative to conventional natural gas, that can be transported and distributed using the existing grid infrastructure.

Wood’s VESTA catalytic methanation technology for natural gas production provides an efficient, robust and viable system that can be adapted to any source of syngas (e.g., from biomass or waste gasification), including the CO2-rich gases typical for biogas upgrading and power-to-gas applications based on green hydrogen and CO2 from other processes.

RNG is a -clean and excellent energy carrier that can be directly introduced into existing natural gas grids. The applications in the bio-based market sector include residential heating (including cooking), cogeneration and transportation systems.

The biogas sector represents a production potential of renewable gas of 10 billion Nm3 of biomethane by 2030 (90% from agriculture matrices and 20% from organic wastes, non-biogenic sources and gasification). The production of biomethane delivers a reduction in greenhouse gas emissions.

Renewable natural gas is expected to play a key role in the energy sector due to the easy connection of production plants to existing natural gas networks and the availability of mature technologies, such as VESTA, for commercial applications.

Wood developed a simple methanation process called VESTA, powered by a high-performance catalyst from our partner, Clariant.

VESTA enables the decarbonisation of natural gas production by exploiting renewable resources with three alternative process schemes to reduce dependency on fossil fuels and meet environmental targets:

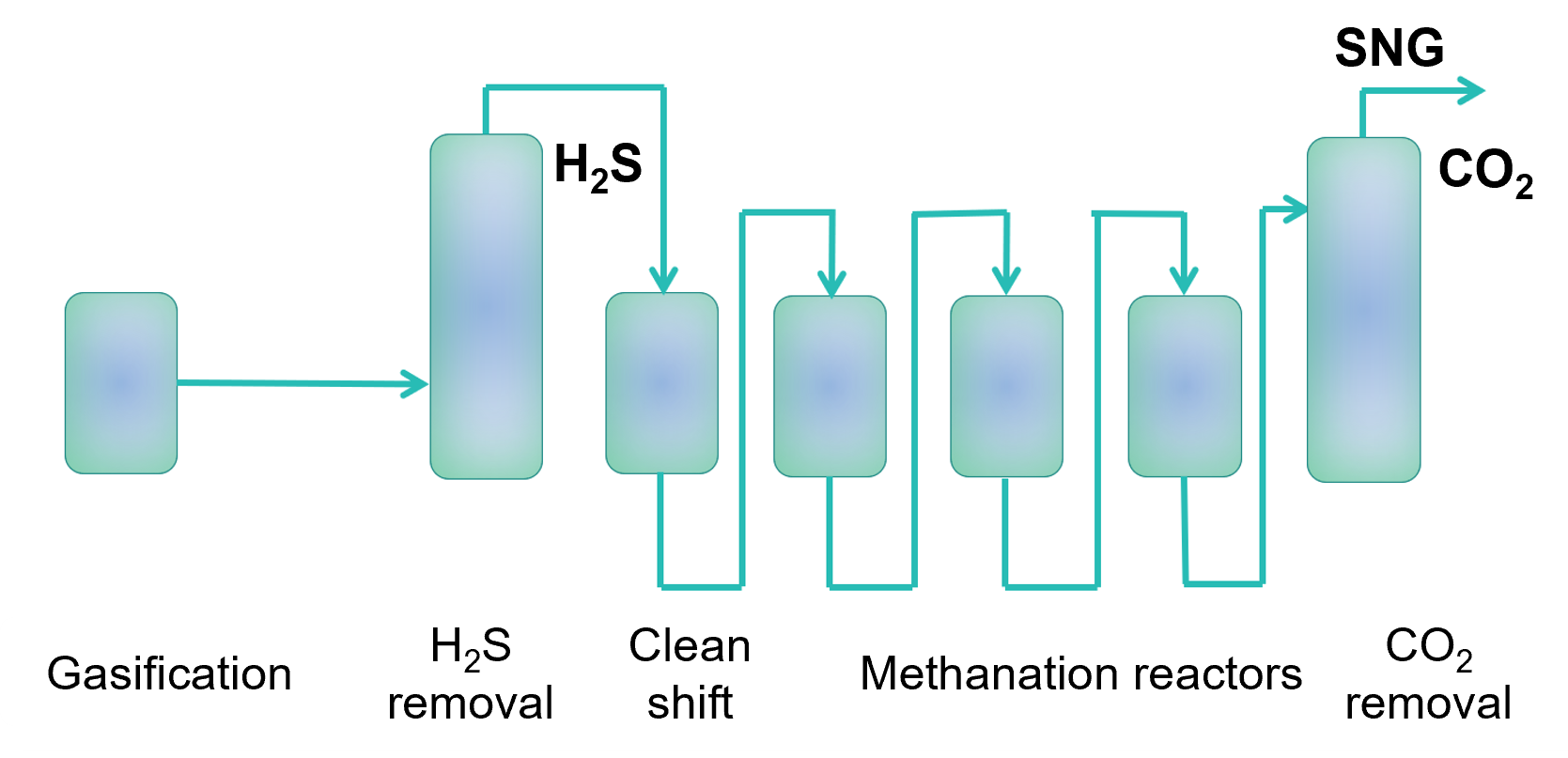

The first pathway to produce a clean gas by using unique plant configurations (depending on the selected gasification technology) with an impact on the downstream syngas compositions and, subsequently, on the cleaning steps.

Biogas and renewable hydrogen to increase Natural Gas production and reduce CO2 emissions

CO2-rich gas conversion to green natural gas by using renewable hydrogen and a subsequent drying section.

Biomass gasification plants can be economically attractive with government incentives across various regions (for example the Advanced Biofuel Feedstock Incentives or Alternative Fuel Corridor (AFC) Grants and similar programmes in the UK and continental Europe), as well as in North America or alternatively as a route to integrate and utilise low grade heat.

Biogas upgrading and power-to-gas systems allows the widest use of RNG, not only for power generation but to provide an alternative for transport, industrial and domestic energy demands in all green economies.

A unique, once-through methanation technology

The advantage of VESTA over the other methanation methods is its full flexibility to balance both capital and operative expenditures, and the adaptation of any source of syngas, such as coal, biomass or waste gasification, biogas upgrading and power-to-gas application.

In contrast to other available technologies, VESTA uses a once-through process with CO2 removal performed downstream of the methanation reactors rather than before the methanation section.

This strategy eliminates the need for product recycle compressors and the associated power consumption and installation costs while prevents the risk of runaway in the Methanation section as the CO2 acts as temperature damper mitigating the High exothermicity of the process.

Catalyst partner

The high-performance catalyst for the methanation reactors is provided by our partner Clariant. Clariant’s high-stability, non-precious metal catalyst is ideal for the increased operating range of 230-700oC contributing to a superior outcome.

Wood has technically and economically assessed the following three SNG production pathways for small-scale and multipurpose commercial applications:

The biobased sector is getting unforeseen interest and investment in Europe. Considering current incentives, biomass gasification followed by a suitable polishing step and clean gas methanation is a viable and economically attractive solution to produce RNG.

Biogas upgrading provides an efficient, robust, and viable system to produce bio-SNG that can be delivered, transported and distributed using existing natural gas infrastructure.

Power-to-gas utilization is as feasible and efficient as biogas upgrading to generate clean syngas and a subsequent bio‑SNG that can be integrated into the existing natural gas networks for transportation and heating.

First of its kind waste-to-SNG demonstration plant

Wood has partnered with the UK government and Advanced Plasma to build the first waste-to-energy SNG plant using the VESTA methanation technology.

The ultra-clean substitute natural gas demonstration plant is funded by the UK’s Department for Transport and by National Grid Gas Distribution and built in collaboration with Advanced Plasma Power’s Gasplasma® technology.

The plant converts biomass to syngas and then converts syngas to substitute natural gas (SNG) using Wood’s VESTA SNG technology. The installation of VESTA methanation is complete and will be fully operational in 2022.